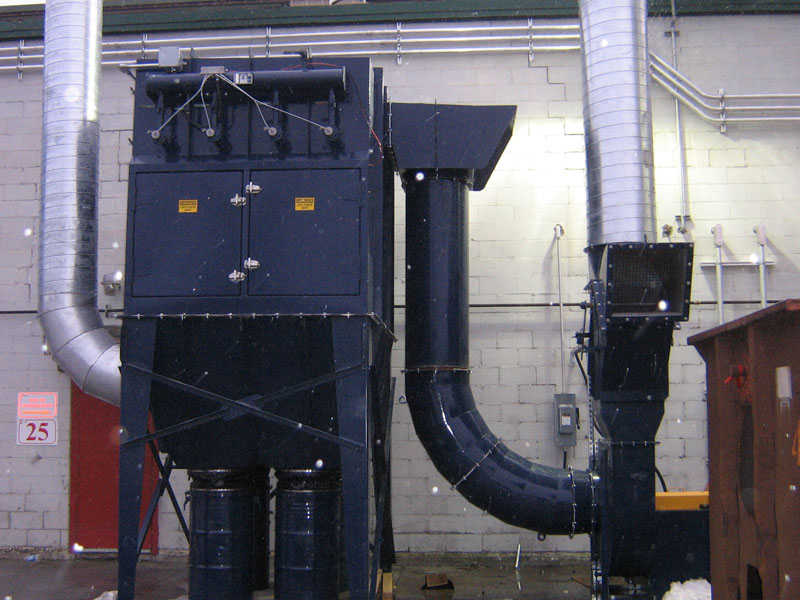

CARTFILTER SERIES DUST FILTERS

The Cartfilter can operate either in negative or positive pressure. The air loaded with particles and dust enters the dust collector through one or several air entrances in the hopper. Gravity projects the heavier particles into the lower part of the hopper where they are continuously collected by a pneumatic, mechanical or storage system. The finer dust is captured upward in the filtering section with vertically installed filter cartridges. The clean air is returned to the plant or to the atmosphere.

The filter cartridges laden with fine particles are cleaned continuously with an air-pulse jet system controlled by a sequential timer.

The Cartfilter cartridge upkeep ensures a perfect seal as well as simple, efficient, and easy maintenance.

The design of the Cartfilter is based on the speed at which the treated particles rise in order to reduce to a minimum the dust load on the cartridges during their operation.

Rodrigue Métal has developed a whole range of remarkably efficient Cartfilters based on research and development as well as on our numerous accomplishments.

APPLICATIONS

- Filtration of all types of dry or damp particles in low or high concentrations

- Welding fumes

SELECTION CRITERIA

- Type of product to be filtered

- Concentration

- Grain size

- Air volume

- Gas temperature

- Gas humidity

- Corrosive agents

CONSTRUCTION

- Mild steel

- Wear-resistant steel

- Stainless steel

AVAILABLE FILTERING CARTRIDGES

- Cellulose paper

- Polyester fiber

- 80-20 cellulose- polyester

Click on the image to enlarge. |